The pillow packaging machine employs a horizontal continuous packaging structure, enabling fully automated feeding, wrapping, and sealing without manual intervention. It is suitable for single-item and multi-item packaging in industries such as food, daily chemicals, hardware, and medical consumables.

The machine operates at speeds ranging from 5 to 200 bags per minute, with optional standard motors or high-precision servo motors to accommodate varying production demands. Utilizing advanced HFFS (Horizontal Form-Fill-Seal) technology, multiple photoelectric sensors ensure precise positioning, delivering consistent and stable packaging appearance for each product.

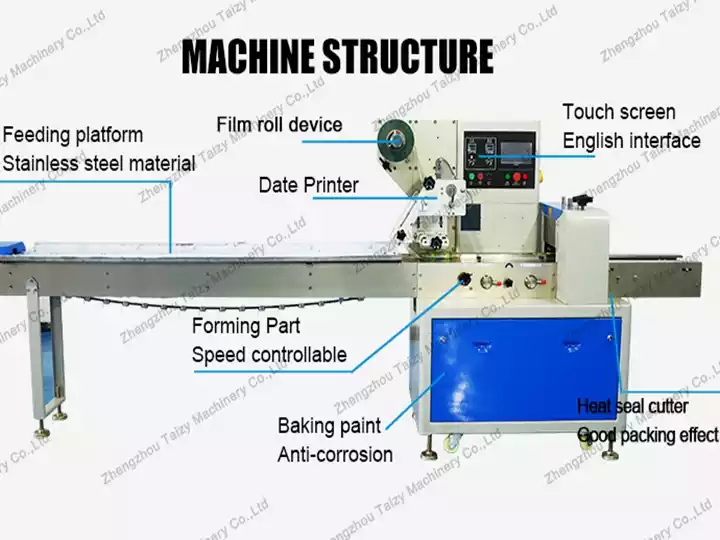

Its intelligent PLC touchscreen system supports multilingual interfaces, rapid parameter switching, and real-time data monitoring, enabling efficient adjustments to critical settings like packaging speed, pouch length, and sealing temperature. Constructed entirely from stainless steel for corrosion resistance and hygienic safety, it represents an ideal choice for achieving automated, standardized, and clean packaging in medium-to-large production lines.

Wide range of applications (by industry)

Our pillow packaging machine is a multi-purpose solution, covering dozens of packaging applications from food to industrial sectors.

High-speed packaging for various food items of different shapes and sizes:

- Snacks: potato chips, puffed snacks, nuts, candies, chocolates, egg rolls

- Baked goods: bread, cakes, cookies, twisted dough sticks, pastries

- Fresh produce: apples, oranges, carrots, pre-packaged fruits and vegetables

- Frozen foods: frozen meatballs, quick-frozen snacks, frozen vegetables

Industrial & Hardware components

Suitable for packaging: Screws, bolts, small hardware assemblies, electronic components, chargers, earphones, cables, etc.

Household & Personal care products

Packaging scope includes: soap, wipes, tissues, toothbrushes, cosmetic samples, travel-size toiletries, etc.

Medical & Protective equipment

Suitable for: medical masks, gloves, protective gowns, surgical drapes, small medical devices, syringes, etc.

Other industries

- Tobacco products: hookah charcoal, cigars

- Agricultural products: seeds, small fertilizer packets, feed pouches

- Cultural & creative gifts: greeting cards, toys, office supplies

Core advantages of pillow packing machines

- High-speed stable operation: utilizing servo drive and multi-link film frame structure, packaging speed reaches 200 packs/minute with smooth operation and no film jamming.

- Intelligent control system: equipped with PLC + large-screen touch interface, supporting multi-language switching. Features convenient parameter settings, fault alarms, and real-time monitoring.

- Robust customization and expansion capabilities: configurable with single/double/triple blades, top/bottom film feed, servo/standard feeding systems, and expandable with inkjet coding, labeling, nitrogen flushing, and other modules.

- High-quality sealing performance: independent PID temperature control system adapts to various packaging films, ensuring secure, aesthetically pleasing seals with minimal breakage risk.

- Food-grade materials and durable construction: primary contact components are stainless steel, ensuring hygiene, corrosion resistance, and easy maintenance.

- Comprehensive safety protection: equipped with multiple safeguards including over-temperature, overload, and anti-finger-cut mechanisms to ensure operator safety and reliability.

Horizontal pillow packaging machine workflow

The pillow packaging machine primarily consists of a PLC control system, conveyor feeding mechanism, forming device, heat sealing system, cutting system, film roll assembly, and discharge conveyor. The workflow is as follows:

Automatic film feeding

Packaging film is automatically conveyed through the film frame into the forming zone. Products are automatically arranged by the conveyor chain and precisely delivered to the packaging position, ensuring continuous and stable feeding.

Bag forming and side sealing

Upon entering the forming unit, the film is rolled into a tubular bag shape while products are simultaneously inserted. The sealing system then heats and presses the film edges to create secure longitudinal and transverse seals.

Optional gas treatment

Optional nitrogen filling or vacuum systems can be configured to regulate the internal gas environment, suitable for food preservation or shock/moisture-proof packaging.

Automatic cutting into bags

The cross-seal cutter severs the continuous packaging film at preset lengths, separating sealed products into individual pillow-shaped bags.

Finished product output

Completed packages are neatly conveyed via the discharge belt for case packing or subsequent processing, enabling fully automated operation.

Factors to consider when selecting a pillow packing machine

When selecting a pillow packaging machine, the following key points will help you quickly determine the model best suited to your product and production requirements:

- Product dimensions and shape: confirm product size and type. As machine adjustability is limited, it is recommended to keep the number of size variations to no more than five.

- Product characteristics: select appropriate feeding and packaging methods based on whether the product is highly sticky, soft, or requires multi-item bundling.

- Packaging film type: ensure machine compatibility with the film material (e.g., PE, PVC, PP), width, and thickness. Specify in advance whether printed patterns are present.

- Speed requirements: clearly define the required packaging output per minute and select the matching speed range.

- Optional feature requirements: select additional configurations based on actual packaging processes, such as nitrogen flushing, vacuum extraction, coding, or labeling.

Technical specifications

We offer a variety of pillow packaging machine models for selection. Below are the specifications for two models. For more machine specifications, please feel free to contact us anytime.

| Model | KT-250D | KT-250B |

| Film width | Max.250mm | |

| Bag length | 65-190mm or 120-280mm | Double cutting knife 90~220mm or One cutting knife 150-330mm |

| Bag width | 30-110mm | |

| Product height | Max.40mm | Max.55mm |

| Film roll diameter | Max. 320mm | |

| Packing speed | 40-230 bags/min | |

| Power source | 220V,50/60Hz,2.4KW | |

| Machine size | (L) 3770mm× (W) 720mm× (H) 1410mm | |

| Machine mass | About 500kg | |

| Remarks | Optional Inflatable device | |

Contact us

Selecting the right pillow packaging machine not only boosts packaging efficiency but also enhances product competitiveness and market presentation.

Taizy Machinery offers multiple models to meet diverse production capacities and application scenarios, while also manufacturing vacuum packaging machines. If you’re unsure which model to choose, feel free to contact us anytime for professional selection advice. We’ll provide you with the fastest and most suitable solution!