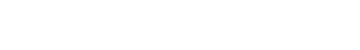

The biscuit production line consists of a blender (dough mixer), a biscuit forming machine, a hot-air rotary roaster, and a biscuit packing machine. The raw materials are firstly seasoned and stirred in a dough mixer, and then subjected to the multi-pass pressing of a biscuit forming machine to prepare raw biscuit embryos. The raw biscuit embryos are placed in a hot air roaster to be baked. After cooling, they can be packed directly.

Video–How to make biscuits by biscuit production equipment

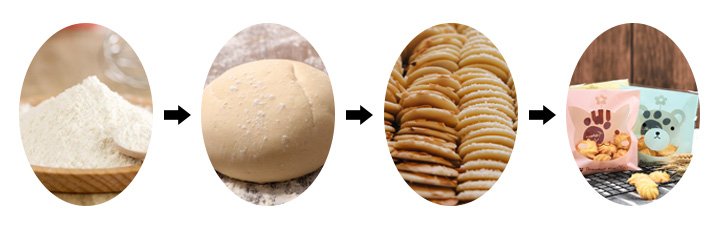

The process of making biscuits

Preparation of raw materials for making biscuits (stirring, seasoning) – biscuit press and molding – baking – cooling – packaging.

Related biscuit production equipment

Mixer – biscuit forming machine – biscuit roaster machine – biscuit packaging machine

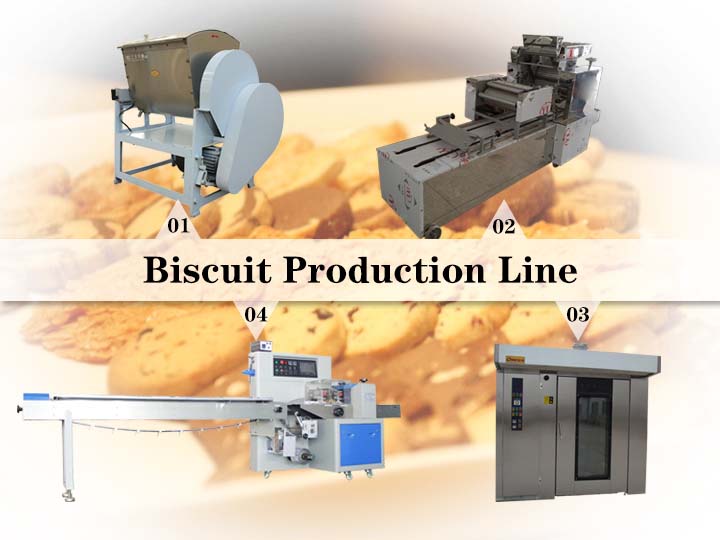

As shown in the picture, by changing the molds, you can make many shapes of cookies. What shapes of cookies do you want to make? Feel free to contact us.

Introduction to the steps of the automatic biscuit production line

Step 1: Preparation of raw materials (biscuit mixer machine)

Before making biscuits, it is necessary to stir water, flour, milk, eggs, white sugar, and other raw materials in a certain proportion to make dough with a certain toughness. The mixer, also known as the dough mixer, consists mainly of a barrel, a stirring roller, a fuselage, a motor, and a sealing cover.

The solid mixing roller is powerful and capable of mixing materials better. The cookie dough mixer machine can automatically flip 90 degrees for easy to pick out the dough.

| Type | Output(kg) | Time required(min) | Voltage(v) | Power(kW) | Weight(kg) | Size(mm) |

| TZ-12.5 | 12.5 | 3-10 | 220/380 | 1.5 | 100 | 650*400*730 |

| TZ-25 | 25 | 3-10 | 220/380 | 1.5 | 128 | 685*480*910 |

| TZ-37.5 | 37.5 | 3-10 | 220/380 | 2.2 | 175 | 840*480*910 |

| TZ-50 | 50 | 3-10 | 220 | 2.2 | 230 | 1070*570*1050 |

| 380 | 2.575 | 275 | ||||

| TZ-75 | 75 | 3-10 | 380 | 3.75 | 475 | 1410*680*1250 |

| TZ-100 | 100 | 3-10 | 380 | 3.75 | 490 | 1520*680*1250 |

| TZ-150 | 150 | 3-10 | 380 | 6.25 | 700 | 1710*730*1400 |

The above are the specific parameters of the biscuit mixer machine. The output, voltage, weight, and size of different machines are different.

Step 2: Biscuit pressing and forming (biscuit forming machine)

This cookie press machine is the most important in the biscuit production line. It is mainly composed of a feeding hopper, a nip roll, a mold roll, a sprinkler box, a conveyor belt, and a fuselage. Place the dough in the hopper of the biscuit molding machine. The material will form a dough cake on the nip roll, and the mold roll and the nip roll will move relative to each other, and the dough cake is pressed into the mold box, and the pattern is printed.

The pressed biscuit embryos are automatically released from the mold and transported along with the conveyor belt. This cookie making machine does not produce waste, and the biscuits produced are not easily broken and are easily released. Customers can change the mold of the biscuit molding machine according to their own needs and adjust the thickness of the biscuit. The adjustment method is very easy.

| Model | TZ-C200 | TZ-C400 | TZ-C600 | TZ-C800 | TZ-C1000 |

| Capacity | 100kg/h | 200-250kg/h | 400-500kg/h | 600-700kg/h | 800-1000kg/h |

| Power | 1.5kw | 1.5kw | 3kw | 4.5kw | 5.5kw |

| Voltage | 220v/380v 50Hz | 380/220v 50Hz | 380/220v 50Hz | 380/220v 50Hz | 380/220v 50Hz |

| Size of Trays | 200*600mm | 400*600mm | 600*600mm | 800*600mm | 1000*600mm |

| Machine Size | 1220*600*1280mm | 2100*950*1350mm | 2100*1150*1350mm | 2500*1350*1350mm | 2100*1550*1600mm |

| Weight | 400kg | 650kg | 950kg | 1300kg | 1500kg |

In Taizy machinery, we have 5 cookie press machines with different outputs for you to choose from. If you have a small biscuit plant, we have machines with an output of 100kg per hour for you to choose from. If you have a large biscuit factory, we have machines with an output of 1000kg per hour for you to choose from.

In addition, for different budgets and customers, we have automatic cookie making machines, semi-automatic cookie production machines and manual biscuit maker machines for sale. These machines can make not only single color cookies but also two color cookies. The material and machine contact parts are made of stainless steel. This machine is a must-have machine for individual bakeries, and bakery factories.

Step 3: Biscuit roast ( Cookie baking machine)

The biscuit roasting machine is very important in the biscuit production line. It is mainly composed of a baking room, a cart, a rotating device, a heating device, and the like. After the biscuits are placed in the baking chamber, they will rotate at a certain speed to ensure uniform heating. Different baking times and temperatures can be set depending on the recipe of the biscuit.

After the baking is completed, the biscuit oven machine will automatically alarm, saving effort. The equipment has two heating methods (electric heating and fuel heating), using the principle of hot air convection and hot air circulation, plus a water spray heating device, especially suitable for high-quality biscuits, bread, and other baking.

| Heating method | Electric heating | Fuel heating | Gas heating | Coal heating |

| Output | 50~80kg/h | 50~80kg/h | 50~80kg/h | 50~80kg/h |

| Capacity | 16 layers / 16 plates | 16 layers / 16 plates | 16 layers / 16 plates | 16 layers / 16 plates |

| Size of the baking pan | 600*400mm | 600*400mm | 600*400mm | 600*400mm |

| Temperature | 20~300°C | 20~300°C | 20~300°C | 20~300°C |

| Voltage | 380v | 380v/220v | 380v/220v | 380v/220v |

| Power | 3.8kw | 2.2kw | 2.2kw | 2.2kw |

| Size of machine | 2100*1600*2500mm | 2100*1600*2500mm | 2100*1600*2500mm | 2100*1600*2500mm |

| Baking time | 12-30min | 12-30min | 12-30min | 12-30min |

| Weight | 1100kg | 1100kg | 1100kg | 1100kg |

According to different heating methods, our company has four biscuit oven machines. You can choose the right biscuit baking machine for your biscuit production line according to your own needs.

Step 4: Packaging (biscuit packaging machine)

Horizontal biscuit packing machines can be used for continuous packaging of food and non-food materials. High-sensitivity electronic eye positioning accurately so that the packaging machine can be sealed and cut in the exact position. Double inverter control, can work directly after the data is set, no need to debug, no waste packaging film.

The device is equipped with a self-diagnostic fault function, and the fault can be directly displayed on the LCD screen for easy maintenance. It can not only be used in the biscuit production line but also used in many different places.

| Type | TZ-250 | TZ-320 | TZ-350 | TZ-450 | ||

| Film width | Max.250mm | Max. 320mm | Max.350mm | Max. 450mm | ||

| Bag length | 65~190mm or 120~280mm | 65-190 or 120-280mm | 90-220 or 150-330mm | 120~280mm or 65~190mm | 150~330mm or 90~220mm | 130-450mm |

| Bag width | 30~110mm | 50-160mm | 50~160mm | 50-180mm | ||

| Product height | Max.40mm | Max.45mm | Max.60mm | Max.45mm | Max. 60mm | Max.70mm |

| Film roll diameter | Max.320mm | Max. 320mm | Max.320mm | Max. 320mm | ||

| Packing speed | 40~230 bags per min | 40-230 bags per min | 40~230 bags per min | 30-180bags/min | ||

| Voltage / power | 220V,50/60HZ, 2.4KVA | 220V,50/60HZ, 2.6KVA | 220V,50/60HZ, 2.6KVA | 220V,50/60HZ,2.6KVA | ||

| Size of machine | (L)3920×(W)670×(H)1320mm | (L)3770X(W)720X(H)1450mm | (L)4020×(W)745×(H)1450mm | (L)4020×(W)820×(H)1450 | ||

| Weight | 800Kg | 900kg | 900Kg | 900Kg | ||

Taize’s four biscuit packaging machines can meet your different packaging needs. Each machine can meet the requirements of different bag lengths, bag widths, and product heights.

If you have any special needs, please feel free to contact us and we will reply to you in time. What’s more, if you need other machinery like cake making machine and egg roll machine. You can also contact us.

Why choose this biscuit production line?

- This cookie production line consists of four machines in total. Although the machine is small, the floor space is small, but the functions are complete and cost-saving.

- Each cookie machine is made of high quality 304 stainless steel, clean and hygienic.

- In addition to the dough mixer, other machines are controlled by electronic intelligence, which is easy to operate and easy to update.

- A biscuit molding machine can produce a variety of different shapes of biscuits, and the mold replacement is simple.

- Cookie pattern support customization. We will provide customers with reference patterns, but if customers want to design their patterns, we will also design according to customer requirements.

How to make biscuits?

According to the taste, biscuits can be divided into crisp biscuits and tough biscuits. The main raw material of biscuits is wheat flour, in addition to sugar, starch, oil, dairy, egg, flavor, and leavening agent. The raw materials and auxiliary materials are prepared into a dough by a dough mixer. Then the molding machine presses the dough into a cake blank and is finally baked in an oven to form a crispy and delicious biscuit after cooling.