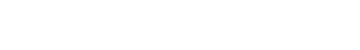

The low-temperature vacuum fryer is used for food processing under negative pressure. The food not only has low oil content but also has complete nutrition and a crisp taste. At present, this machine is often used to make fruit and vegetable chips.

What are the advantages of low-temperature vacuum frying?

Compared with the traditional frying method, low-temperature vacuum frying is more healthy. When the oil is at a high temperature (the traditional frying method, the oil temperature usually reaches 160 degrees Celsius or higher), it is easy to produce oxidation reaction and polymerization reaction, as well as carcinogens.

High cellulose, high pectin, and materials rich in sugars and amino acids are not suitable for traditional frying methods. For example, apples, bananas, onions, garlic, etc., high-temperature frying will not only destroy the original nutrients of food but also produce carcinogens such as acrylamide.

The scope of application of low-temperature vacuum fryer:

- Fruits: apple, banana, kiwi, strawberry, mango, jackfruit, etc.

- Vegetables: mushrooms, okra, bamboo shoots, pumpkin, carrots, sweet potatoes, onions, garlic, etc.

- Meat: beef, chicken, fish, squid, shrimp, etc.

All in all, the low-temperature vacuum fryer has a wider range of applications and is suitable for processing a wide range of materials.

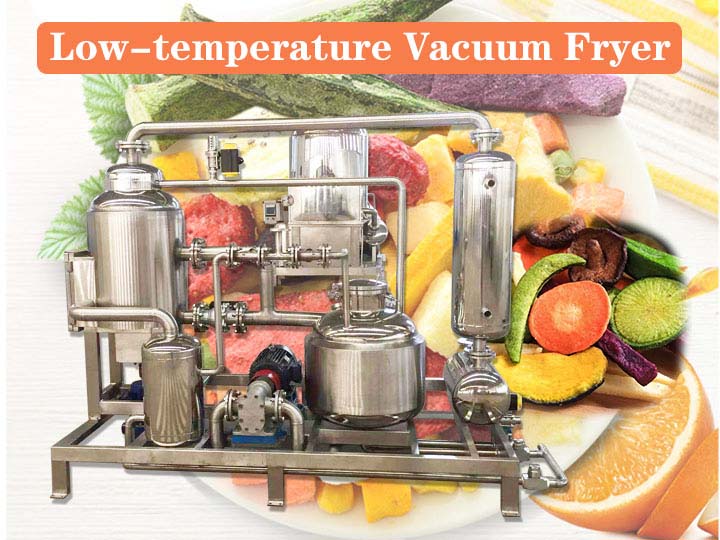

The structure of the fruit and vegetable chips making machine:

Structure composition:

This machine is mainly composed of a vacuum fryer, oil filtration system, oil circulation heating system, vacuum system, water vapor capture system, automatic deoiling system, electrical control system, and so on.

Working principle:

This equipment uses hot oil as the medium and adopts the advanced technology of low-temperature vacuum frying. In the vacuum state, the pressure difference will be formed. Under the effect of pressure difference, the speed of material diffusion and gas diffusion is accelerated, the moisture of material evaporates rapidly, and the taste is crisper. At the same time, it can inhibit the fatty rancidity, enzymatic browning, and oxidative deterioration of food materials.

How to use the low-temperature vacuum fryer:

- Turn on the power switch and enter the parameter setting panel of the machine. The appropriate frying time, frying temperature, deoiling time, and deoiling frequency are set according to the type of food and the weight of the frying.

- Add oil to the storage tank and preheat the machine. Turn on the oil heating switch, and the machine will automatically start (close) the steam solenoid valve according to the set temperature to start heating the oil.

- When the oil is heated to the required temperature, put the material in the vacuum fryer.

- Close the pot door – close the vacuum valve – start the oil heating – start the cooling water – start the vacuum pump unit.

- When the vacuum reaches -0.09~-0.092MPa, start automatic frying.

- The oil enters the fryer from the storage tank through the steam heater. During the frying process, the basket is automatically rotated during the frying process and the material is in a fully dynamic suspension frying process.

- When the set frying time is reached, the oil in the fryer is returned to the storage tank. It is filtered on the filter net inside the storage tank. (The oil residue needs to be cleaned once a month or half a month)

- After the reflux is completed, the machine is subjected to vacuum centrifugal deoiling. After the deoiling is finished, the buzzer will automatically alarm and the frying process will end.

How to make the fruit and vegetable chips?

Fruit and vegetable chips production process:

Raw materials → screening → cleaning → slicing (cutting) → color protection (bleeding) → draining → freezing → vacuum frying → vacuum deoiling → seasoning → product packaging → storage.

Related machinery and equipment:

Fruit and vegetable washing machine – multi-function cutting machine – blanching machine – dehydrator – freezer – low-temperature vacuum fryer – seasoning machine – packaging machine

Fruit and vegetable chip machine parameters:

| Type | VF-1200 | |

| Capacity(raw material/ kg) | 200-240 | |

| Time consuming(min) | About 40 min per time | |

| Ultimate vacuum (MPa) | -0.1 | |

| Oil temperature (°C) | 80~120 | |

| Heating source | Heating source | steam |

| Steam consumption (Kg/h) | 250 | |

| Steam pressure (MPa) | 0.3~0.5 | |

| Main heating method | Oil pump external circulation | |

| Deoiling number (n/min) | 0~400 | |

| Cooling water volume (T/h) | 40 | |

| Power supply | Voltage | 3N~380~ |

| Total power (Kw) | 33KW | |

| Size (mm) | 5800*2000*3700mm | |

Features of low-temperature vacuum fryer:

- The manufacturing technology of the steam solenoid valve is constantly updated, and now the technology is mature. The temperature control effect is more stable, which can be repaired and replaced in the working process.

- The use of an oil-water separation system can ensure the quality of oil, increase the number of oil recovery and utilization, and save costs.

- The vacuum pump system can reach the ultimate vacuum, delay the oxidation rate of the oil, ensure the crisp taste of the food, and reduce the running noise of the equipment.

- The vacuum fryer is connected by a plurality of stainless steel brackets to reduce the pulling force during the working process, and the deoiling work is more stable.

- Increase the exchange area of the steam heat exchanger, the oil temperature is more stable and more easily heated. The heating time is shortened and the production efficiency is high.

- Vertical condenser to facilitate the outflow of condensed water.

- The basket in the fryer adopts a hollow design, which not only accelerates the frying process but also reduces the rotating load.

- The deoiling process uses dynamic balancing to ensure that the vibration during the deoiling process is minimized.