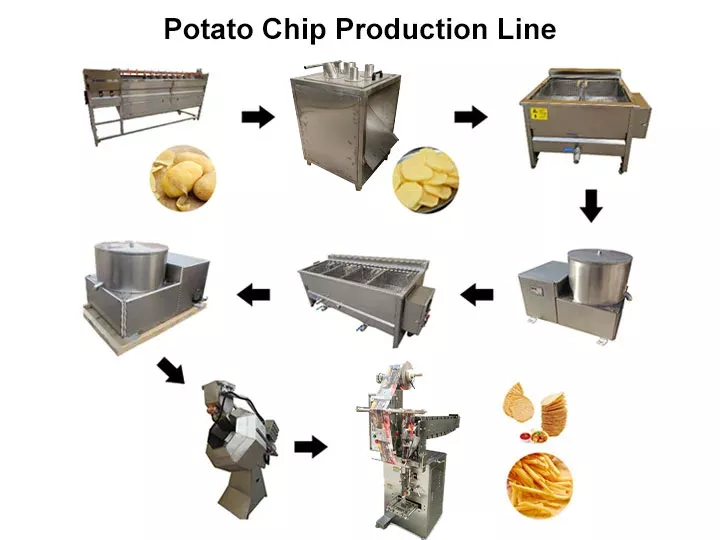

The potato chips production line is composed of a variety of machines. There are two kinds of potato chip production lines, automatic and semi-automatic potato chip production line. This article mainly introduces the main machines in the automatic potato chip production line.

Video of potato chips production line

How to make potato chips?

What machines are needed to form a fully automatic potato chips production line?

Here is the main working flow of the automatic potato chips production line: Conveying — washing and peeling raw material — cutting potato — blanching — dehydration — frying — deoiling — seasoning

Step 1: Conveying

The hoist is an important machine for dividing automatic or semi-automatic potato chips production lines. It is mainly responsible for the transportation of potatoes processed in each step. Its purpose is to replace manual handling so that each machine in the French fries production line is connected. This machine can save labor costs and reduce the workload of workers.

Step 2: Potato cleaning and peeling

A brush type cleaner is needed for cleaning and peeling. Before making potato chips, muddy potatoes need to be washed in a brush cleaner. When the machine is running, you need to put the right amount of water inside the case and then put the potatoes.

The potatoes are constantly rubbed against the brush during the tumbling process so that the dirt and skin on the outside of the potatoes can be removed. The brush is made of rigid nylon material, durable and wear-resistant, with a high peeling rate of over 95%.

Parameters of brush type cleaner

| Type | Capacity (kg) | Power(kw) | Dimension (mm) | Weight (kg) |

| TZ-800 | 800 | 1.5 | 1500*700*600 | 220 |

| TZ-1200 | 1200 | 2.2 | 1800*860*850 | 300 |

| TZ-1500 | 1500 | 3 | 2100*860*850 | 360 |

| TZ-4000 | 4000 | 5.5 | 3050*1200*1160 | 600 |

Four different brush type cleaners have different production capacities. The output is 800 kg/h, 1200 kg/h, 1500 kg/h and 4000 kg/h respectively. Depending on the output, the size of the brush type cleaner also varies greatly. The dimensions are 1500x700x600 mm, 1800x860x850 mm, 2100x860x850mm, and 1050x1200x1160 mm respectively.

Step 3: Slicing

Potato slicer machine

This potato slicer machine is very suitable for potato slicing, and cutting. It can be used not only to make regular potato chips but also to make wavy potato chips. The switch between the two is very simple, just need to change the cutter.

Although the size of this machine is very small, it is very efficient and can produce 300-600kg/h. The whole machine is made of 304 stainless steel and is equipped with safety devices. It is not only beautiful but also safe and convenient to use.

Cutting detail

| Ding size/mm | Slice size /mm | 1-10 waves can be customized |

| 6,8,10,12,15,20,25 | 1-10 wave can be customized | 2-8, 10 can be customized |

| 8,10,12,15,20 | 2-10 | 2-10 |

Technical data of potato cutting machine

| Name | Model | Size | Weight | Power |

| single-head cutter | CY-865 | 750*520*900MM | 70KG | 750W |

French fries cutting machine

The French fries cut by the potato slice cutting machine are the same size and have no waste. The thickness of the cut fries can be adjusted, and the adjustment range is between 6-12 mm. If you have other needs, you can contact us for customization.

The body of this machine is made of 304 stainless steel, and the cutter material is thickened carbon steel, which can extend the service life of the machine to some extent. Its output can reach 300-600 kg per hour. The machine is designed reasonably, and the feed port is enlarged to facilitate feeding.

Technical data of potato slice cutting machine

| Capacity | Dimension | Power | Voltage | Weight |

| 600kg/h | 950*800*950mm | 1.1kw | 380/220v | 110kg |

Potato peeling and cutting machine

This potato peeling and cutting machine combines cleaning, peeling, and shredding. After the potatoes enter the feeding cylinder, the potatoes are rubbed against the corundum of the inner wall of the feeding cylinder under the action of centrifugal force, and the potato skin can be effectively removed. Skin that cannot be removed because of potato sags can be peeled artificially.

During the rotation of the barrel, the water can be continuously introduced, and the potato skin adhered to the inner surface of the barrel can be washed away.

When the peeling work is completed, the feed bin door can be opened, the potatoes can be passed through the dial to enter the cutter, and the potato strip can be obtained through the cutter processing. This machine is made of all stainless steel, and the cutter is easy to replace. You can cut potato chips or cut potato strips with this machine.

The above three machines are widely used, in addition to potatoes, but also for taro, sweet potatoes, cucumbers, and other vegetables and fruits slicing and cutting.

Parameters of the potato peeling and cutting machine

| Type | Power kW/h | Weight kg | Size mm | Output kg/h |

| QS400-10 | 0.75kw/220v | 100kg | 880*510*980 | 80 |

| QS400-30 | 1.1kw/380v | 130kg | 1130*660*1130 | 150 |

| WD200 | 1.1kw | 120kg | 750*500*1100 | 200 |

| WD400 | 1.5kw | 140kg | 950*700*1150 | 400 |

Four different types of potato peeling and cutting machines have different yields and sizes. The minimum output is 80kg / h and the maximum output is 400kg / h. Therefore, it is suitable for different production requirements. It is the main machine in the potato chips production line.

Step 4: Blanching

The purpose of blanching is to remove the starch from the potatoes and prevent oxidative discoloration during subsequent frying. The blanching machine consists of a heating tube, a built-in net frame, a water outlet, and a machine body.

First, you need to put enough hot water in the body of this machine and preheat it. When the water temperature reaches 80-100 degrees Celsius, cut potato strips or potato chips into the built-in net frame. Boil after 2-3 minutes. The water after the blanching can be discharged through the water outlet.

Technical data

| Type | Size (mm) | Weight (kg) | Power(kW) | Capacity | Number |

| CY500 | 700*700*950 | 70 | 12 | 50kg/h | 1 basket |

| CY1000 | 1200*700*950 | 100 | 24 | 100kg/h | 2 basket |

| CY1500 | 1700*700*950 | 160 | 36 | 150kg/h | 3 basket |

| CY2000 | 2200*700*950 | 180 | 42 | 200kg/h | 4 basket |

| CY3000 | 3300*1100*1300 | 400 | 72 | 300 | 6 basket |

There are five models of blanching machines for you to choose from. The output is 50kg/h, 100kg/h, 150kg/h, 200kg/h and 300kg/h respectively. And different machines have different sizes. Please select the appropriate machine according to your own needs.

Step 5: Dehydration

Potato chips (potato strips) after blanching contain a lot of water. If they are fried without dehydration, it will not only cause splashes of oil and danger but also affect the quality of oil and the taste of potato chips or strips. The centrifugal dehydration de-oiler generates a powerful centrifugal force by flying at a high speed, and the moisture inside the material can be extracted. The dehydration time depends on the situation, usually within 2-4 minutes.

Parameters of the dehydrator

| Capacity | 200kg/h |

| Dimension | 1100*500*850mm |

| Voltage | 380V/220V |

| Power | 1.5kw |

| Weight | 350kg |

Step 6: Frying

This process requires the use of a fryer. This potato frying machine is the same as the blanching machine used in the fourth step. It only needs to change the water inside the case to oil. When the temperature of the temperature measuring gun reaches about 180 degrees, the potato chips can be placed for frying. Generally, the potato chips are fried in 3-5 minutes, and the longer the fried, the crisper the taste. But not too long, otherwise, it will produce a burnt taste.

Frying machine parameters

| Type | Size (mm) | Weight (kg) | Power(kW) | Capacity | Number |

| CY500 | 700*700*950 | 70 | 12 | 50kg/h | 1 basket |

| CY1000 | 1200*700*950 | 100 | 24 | 100kg/h | 2 basket |

| CY1500 | 1700*700*950 | 160 | 36 | 150kg/h | 3 basket |

| CY2000 | 2200*700*950 | 180 | 42 | 200kg/h | 4 basket |

| CY3000 | 3300*1100*1300 | 400 | 72 | 300 | 6 basket |

In Taizy food machinery, we have five potato frying machines for you to choose from. The output is 50kg/h, 100kg/h, 150kg/h, 200kg/h and 300kg/h respectively.

Step 7: Deoiling

Excessive oil content can affect the taste and is not good for your health. Therefore, it is necessary to separate the excess oil from the fried potato chips. The machine used in this process is the same as the centrifugal dewatering machine used in the fifth step. This machine also uses the centrifugal force generated by high-speed rotation to remove the oil from the potatoes. This step is to get crispy potato chips.

Parameters of the Deoiler

| Capacity | 200kg/h |

| Dimension | 1100*500*850mm |

| Voltage | 380V/220V |

| Power | 1.5kw |

| Weight | 1.5kw |

The capacity of this potato deoiler is 200kg/h, and the dimension is 1100*500*850mm.

Step 8: Seasoning

This step requires the use of an octagonal seasoning machine. The deoiled potato chips are put into the machine, and seasoning products are continuously put into the machine for flavoring. This machine can discharge automatically. After mixing and seasoning the potato chips fully, and pulling the control switch on the left side of the machine, the machine can discharge automatically. It’s very convenient and fast to try.

As an important step in your potato chips production line, you need to choose an efficient seasoning machine.

Technical data of the french fries flavoring machine

| Capacity | Dimension | Voltage | Power: | Weight: |

| 300kg/h | 1100*800*1300mm | 380V/220V | 1.1kw | 190kg |

The capacity of this machine is 300kg/h, and the weight is 190kg/h. If you want to know more information about this machine, please feel free to contact us.

Step 9: Packaging

Processed fries or chips can be packaged directly and sold worldwide. We also offer a Vacuum packaging machine that matches this potato chips production line for your reference. In addition to the small French fries production line with a production capacity of 100 kg per hour, we also have a medium-sized production line with a production capacity of 500 kg per hour and a large potato chips production line.

Parameters of the vacuum packaging machine

| Type | Vacuum chamber size(mm) | Seal length(mm) | Voltage(v) | Size(mm) | Vacuum degree ((Pa) | Power(kW) |

| SL-400/2S | 520*500*100 | 400 | 380(220) | 1030*520*910 | ≤ 200 | 2 |

| SL-500/2s | 620*580*100 | 500 | 380 | 1220*580*910 | ≤ 200 | 2.5 |

| SL-600/2s | 720*620*100 | 600 | 380 | 1430*720*950 | ≤ 200 | 3 |

| SL-700/2s | 820*720*100 | 700 | 380 | 1630*810*950 | ≤ 200 | 4 |

| SL-800/2s | 920*820*100 | 700 | 380 | 1830*820*950 | ≤ 200 | 5 |

There are five vacuum packaging machines for you to choose from. They have different vacuum chamber sizes and machine sizes. You can purchase it according to your own needs, If you have any questions, please feel free to contact us, and we will get back to you as soon as possible.

The successful case of the potato chips production line

Customers from Turkey have purchased a potato chips production line with a capacity of 500kg/h. We sent professional technicians to Turkey to guide the installation. At present, the customer is very satisfied with this production line and also sent a feedback video(Click here to watch the video). In addition, we also have a semi-automatic potato chips production line. Because its output is about 100 kilograms per hour, it is also known as a small potato chips production line.

What are the characteristics of the best french fries production line?

- The quality is excellent. Made of stainless steel, the motor adopts an internationally famous brand and is durable.

- Fair price. We adhere to the philosophy of long-term cooperation and will not do a one-time business. So we never deceive customers and try to create a win-win situation.

- Support customization. The machines included in this production line have a variety of different matching methods, you can match according to your needs. Not only that, the size of the machine, the size of the output, etc. also supports customization.

- Various applications. This potato chips production line can be used for the processing of a variety of materials, such as the production of banana chips and other foods.

- Automatic temperature control and over-temperature protection. This fryer is a smokeless, multi-function fryer. Controlled by the electronic control instrument, when the oil temperature is higher than the set temperature, the heating device stops heating. When the oil temperature is lower than the set temperature, the heating device starts to heat, ensuring the product’s frying temperature and improving the product quality.

- Functions are diverse. The potato chips production line can be used to produce french fries, potato chips, and wavy potato chips at the same time. It only needs to change the cutting knife. Satisfy customer’s multiple needs.